Contact Point Corrosion Inspection at its finest

The STIX - 2 Probe PA-CAT Scanner provides a complete AOD (axial, outside diameter) and COD (circumferential, outer diameter) solution for the implementation of pitch-catch techniques like PA-CAT for phased array inspection of contact point corrosion (corrosion under pipe support - CUPS). Capable of operation on pipes 7.6 cm (3 in) and up, the STIX can convert to either axial or circumferential direction.

Customer Photos

Features

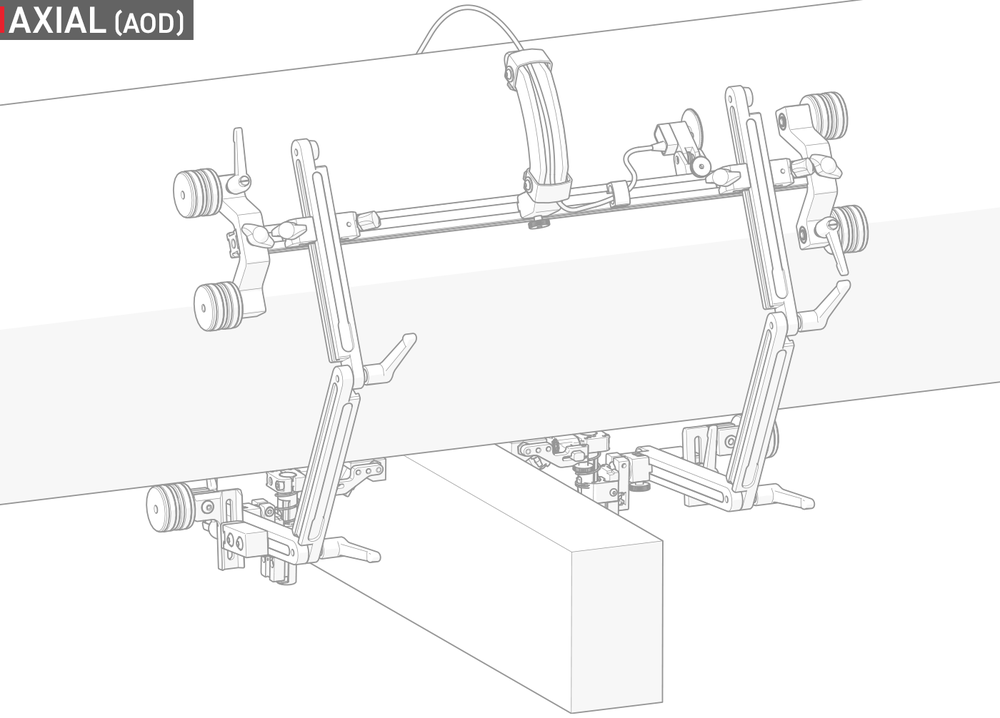

Axial, outside diameter

Perform AOD inspection of contact point corrosion at pipe supports in the axial direction.

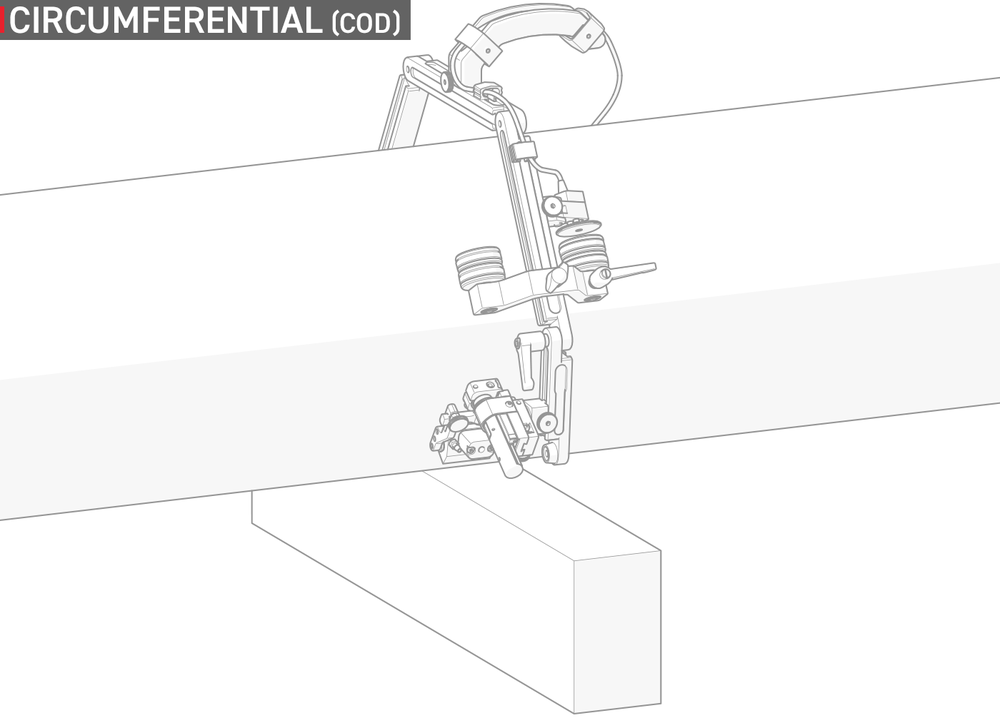

Circumferential, outside diameter

COD allows the user to detect and measure contact point corrosion in the circumferential direction.

Magnetic Wheels

Strong magnetic wheels keep the scanner in place on any ferrous surface.

Handle

The convenient handle also doubles as a cable management solution.

Spring-Loaded Encoder

The spring-loaded encoder provides precise encoded positional feedback to any model of instrument the client chooses.

Vertical Probe Holder

The versatility of the vertical probe holder is on full display when using the STIX - 2 probe PA-CAT scanner. Transverse adjustment, height adjustment, and angle adjustment are just a few of the capabilities needed for this probe holder.

Adjustability

The scanner features pivoting frame bars which allow for seemingly limitless possibilities.

Warranty

A three-year limited warranty is included with all JIREH products.

Axial and Circumferential

Axial (AOD)

Axial, outside diameter (Longitudinal)

Minimum pipe diameter: 7.6 cm (3 in)

Maximum pipe diameter: 60.1 cm (24 in)

Circumferential (COD)

Circumferential, outside diameter

Minimum pipe diameter: 7.6 cm (3 in)

Maximum pipe diameter: 60.1 cm (24 in)

Kit Contents

SCANNER

STIX - PA-CAT 2 probe scanner

PARTS & ACCESSORIES

Spring-loaded encoder, 5 m (16.4 ft) cable length

Vertical probe holders with standard, drop arms x2

Magnetic wheels x8

Cable clips x2

Probe holder spare parts kit

4 mm ID irrigation kit (7/16 in quick connect)

Protective sleeving 5m (16.4 ft)

User manual

Quick-reference guide

Rugged carrying case

TOOLS

Loom installation tool

Wrench for pivot button adjustment

3 mm hex driver

Parts & Add-Ons

Related Products

Specifications

GENERAL

Pipe Range, Circumferential: 7.6 cm (3 in) to 60.1 cm (24 in)

Pipe Range, Axial (Longitudinal): 7.6 cm (3 in) to 60.1 cm (24 in)

Encoder Resolution: 9.05 counts/mm (230.0 counts/inch)

Probe Holding Capacity: 2 phased array wedges

Encoder Cable Length: 5 m (16.4 ft)1

Inspection Surface: Ferrous materials

U-Bolt clearance configuration available, Contact JIREH for details

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 50°C (122°F)

Environmental Sealing: Watertight (submersible), Contact JIREH for details

PIPE DIAMETER SPECIFICATIONS

Axial (AOD)

Axial, outside diameter (Longitudinal)

Minimum pipe diameter: 7.6 cm (3 in)

Maximum pipe diameter: 60.1 cm (24 in)

Circumferential (COD)

Circumferential, outside diameter

Minimum pipe diameter: 7.6 cm (3 in)

Maximum pipe diameter: 60.1 cm (24 in)

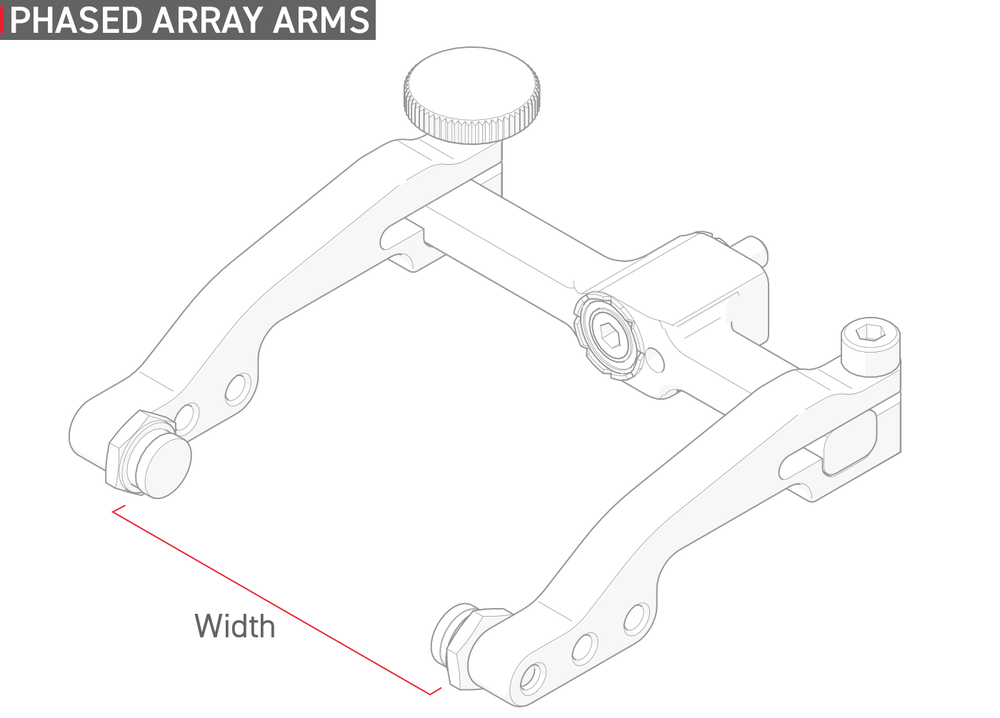

PHASED ARRAY PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 17.1 mm (0.7 in)

Maximum Wedge Width: 57.6 mm (2.3 in)2

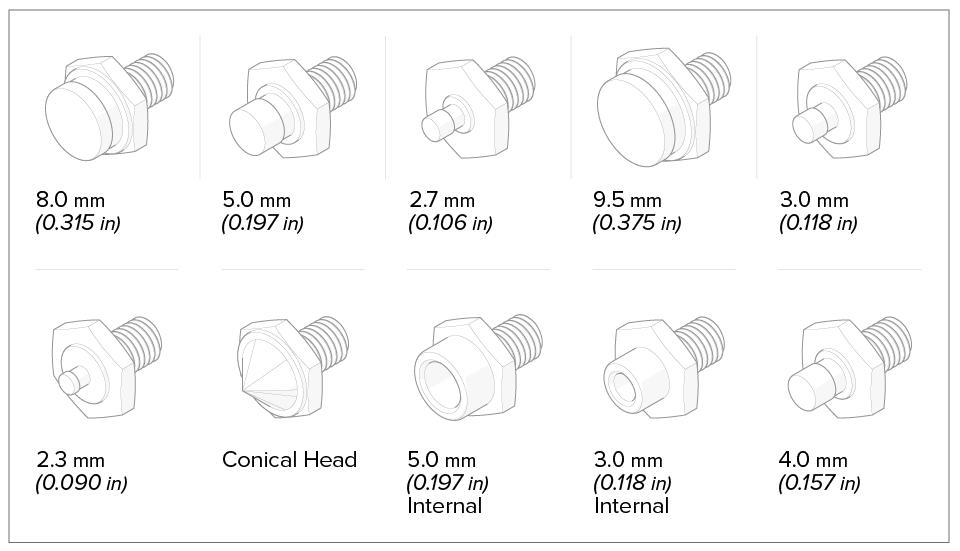

Probe Holder Pivot Buttons

01

Pivot Hole Size: 8.0 mm (0.315 in)

Wedge Type: Olympus PA

Hex Size: 9.53 mm (3/8 in)

02

Pivot Hole Size: 5.0 mm (0.197 in)

Wedge Type: Olympus TOFD, Olympus A27 DMA

Hex Size: 9.53 mm (3/8 in)

03

Pivot Hole Size: 2.7 mm (0.106 in)

Wedge Type: Sonatest DAAH PH

Hex Size: 9.53 mm (3/8 in)

04

Pivot Hole Size: 9.5 mm (0.375 in)

Hex Size: 11.1 mm (7/16 in)

06

Pivot Hole Size: 3.0 mm (0.118 in)

Hex Size: 9.53 mm (3/8 in)

07

Pivot Hole Size: 2.3 mm (0.09 in)

Hex Size: 9.53 mm (3/8 in)

08

Pivot Hole Size: Conical Head

Hex Size: 9.53 mm (3/8 in)

09

Pivot Hole Size: 5 mm (0.197 in)

Wedge Type: Internal Zetec PA/TOFD, Phoenix TOFD

Hex Size: 9.53 mm (3/8 in)

11

Pivot Hole Size: 5.6 mm (0.221 in)

Hex Size: 9.53 mm (3/8 in)

- Custom encoder cable lengths are available.

- Some arm styles may provide additional maximum wedge width. Contact JIREH for details.

Technical specifications are subject to change.