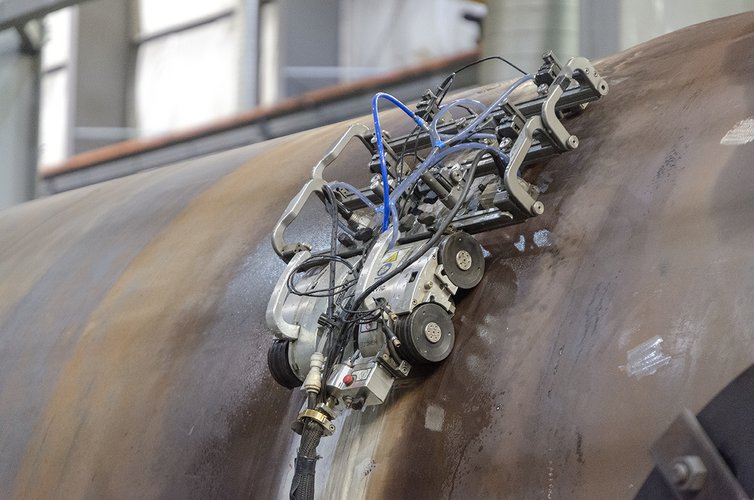

The optimal choice for weld inspection on ferrous surfaces

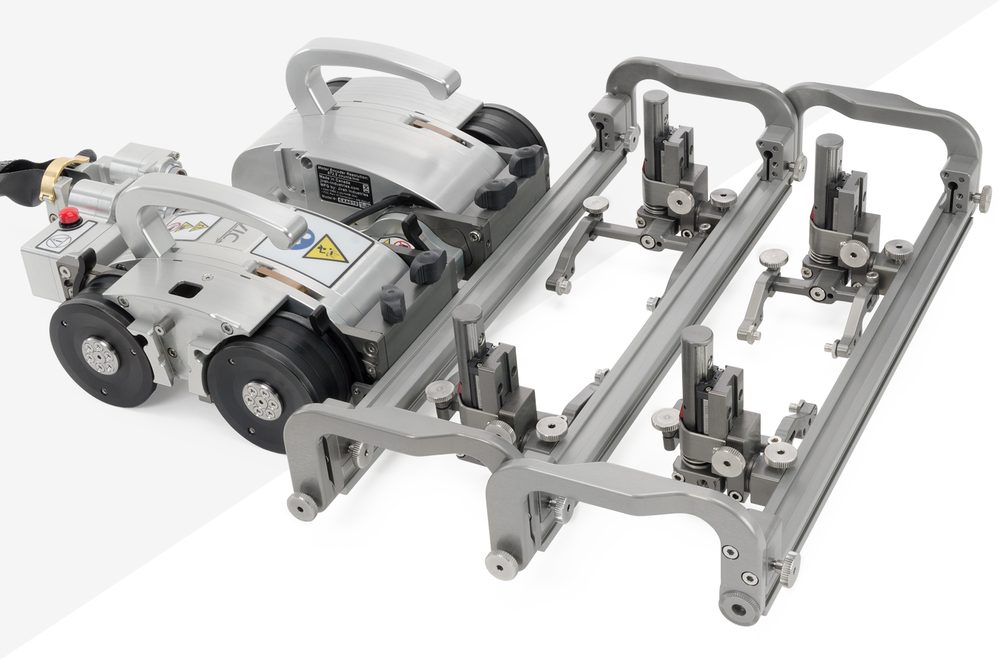

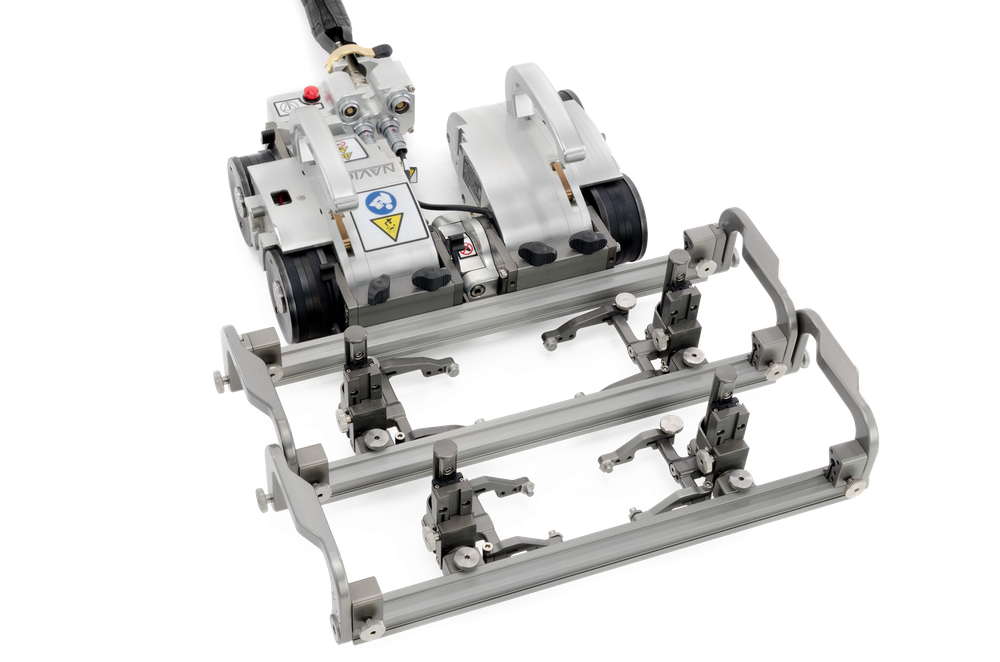

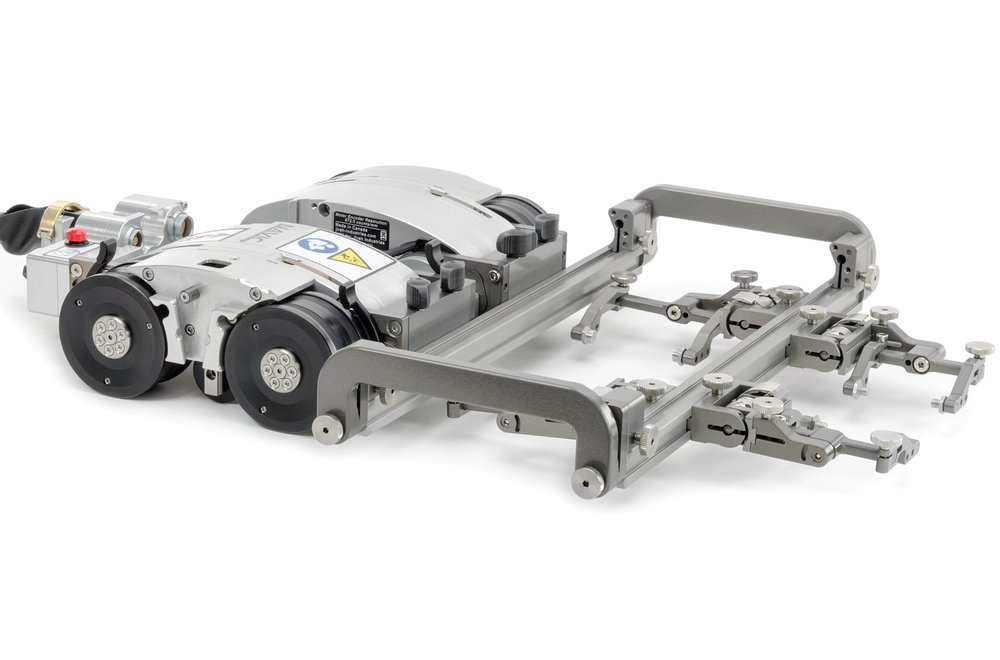

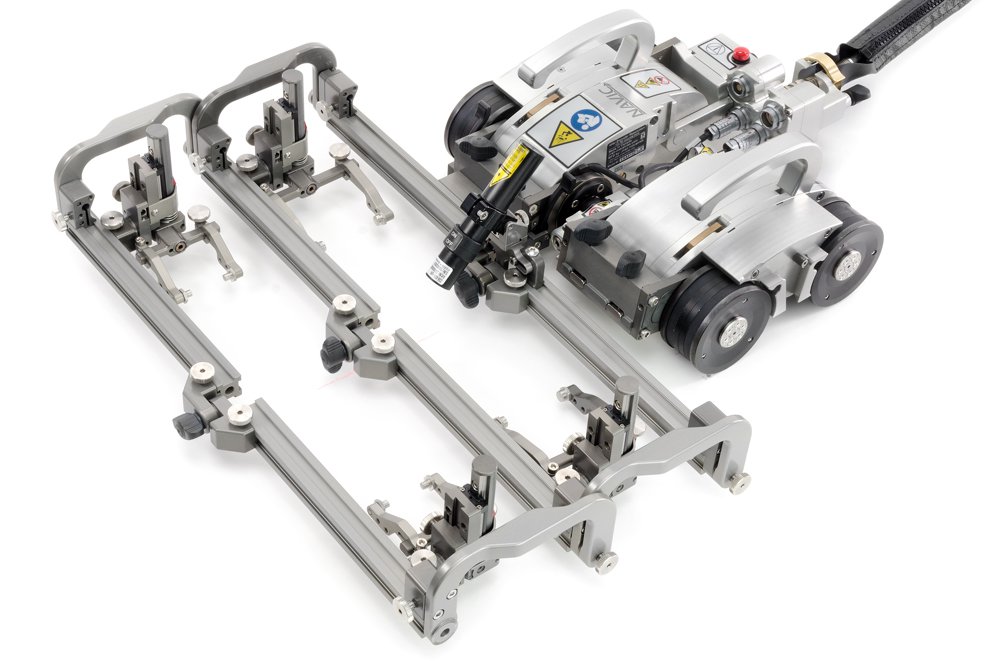

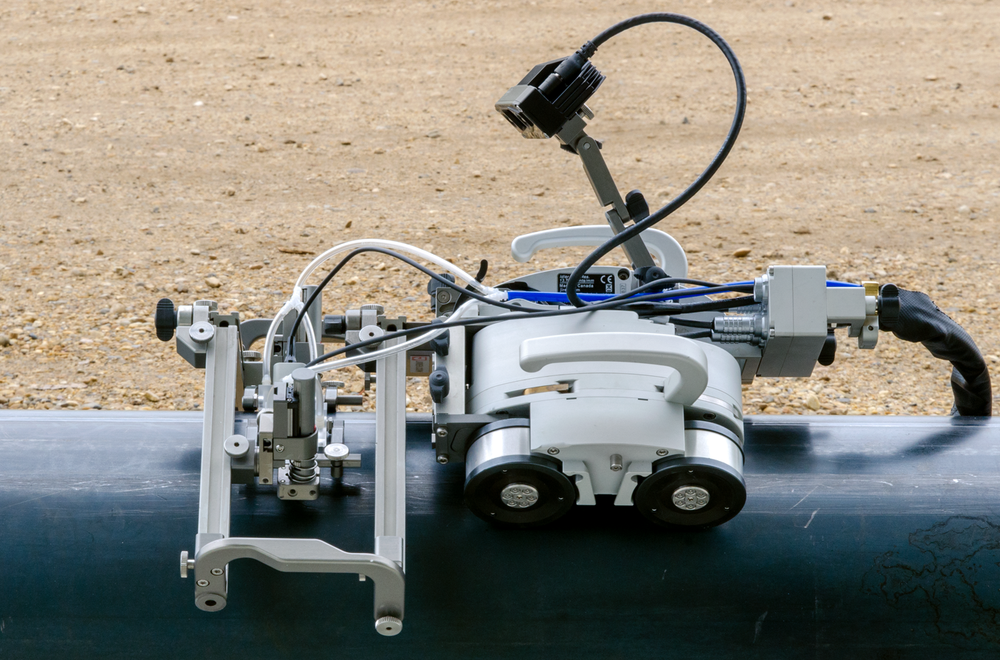

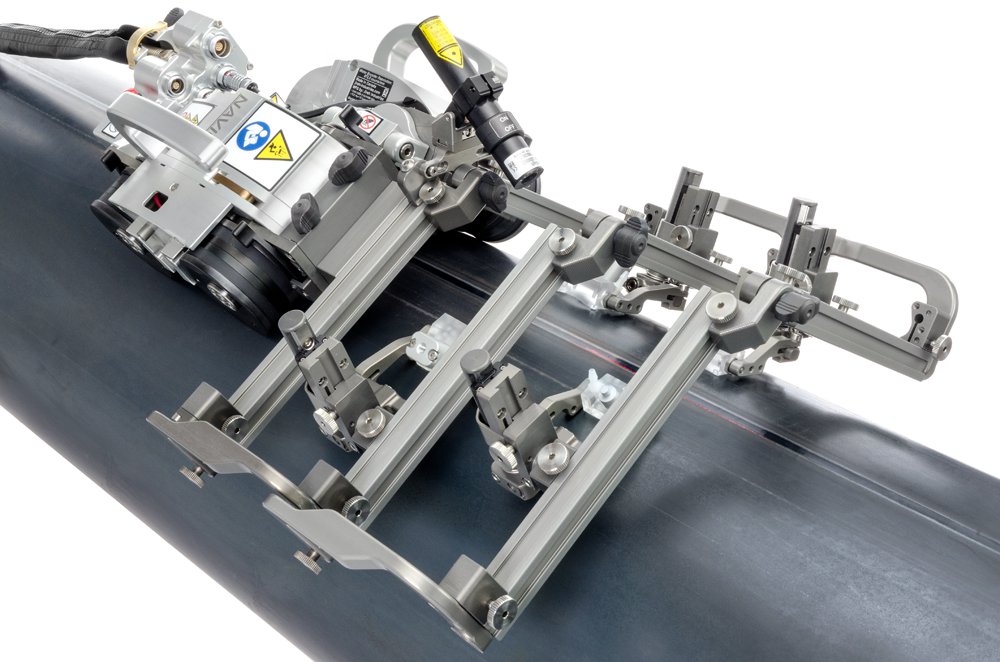

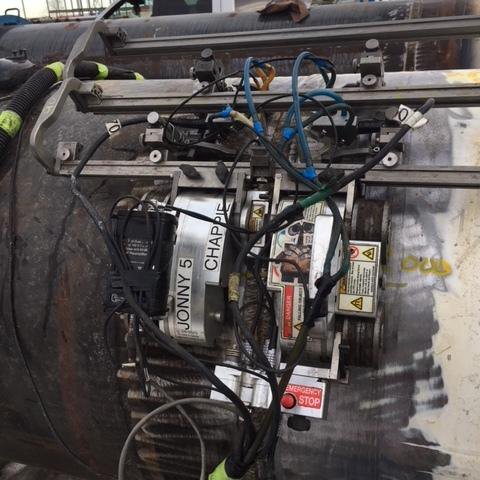

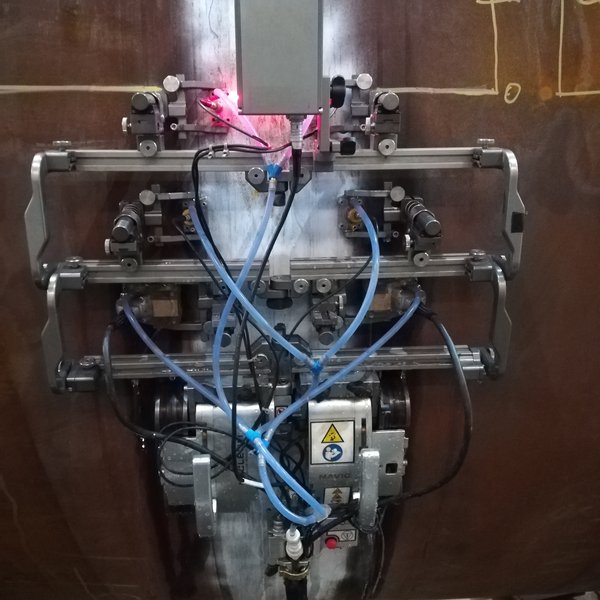

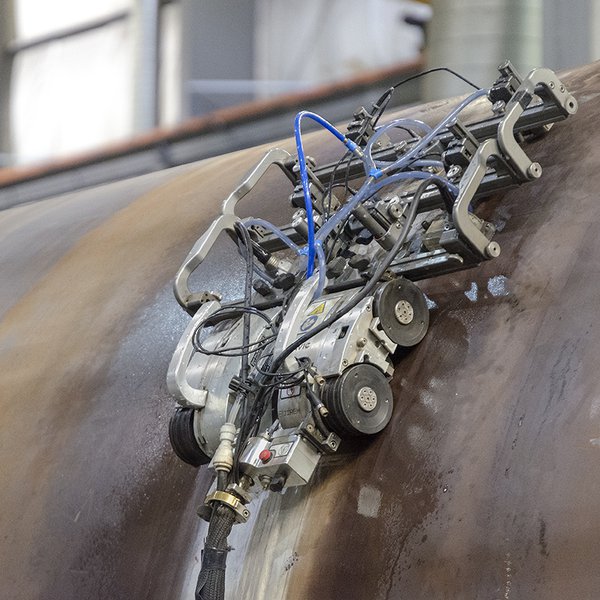

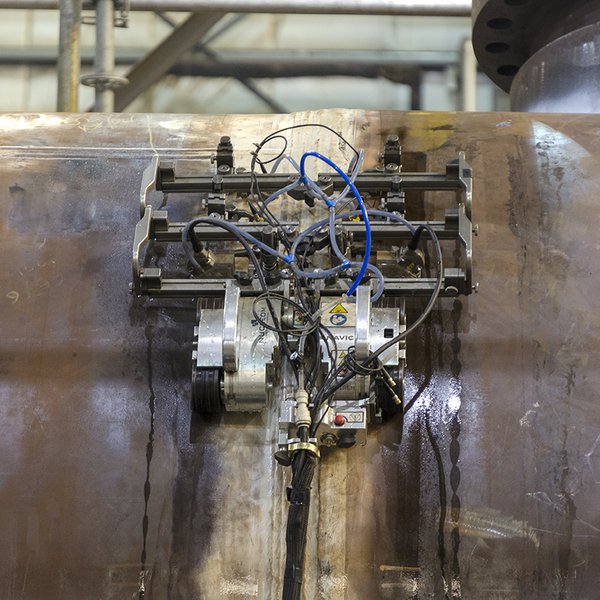

Track welds circumferentially or longitudinally with up to 6 probes. Follow welds with the steerable, remote-operated NAVIC Weld Scanner, equipped with magnetic wheels, which allow vertical and inverted weld inspection to be performed easily. Various probe holder frames expand the weld scanning possibilities. From low-profile for restricted access to spiral welds and long seam inspection, the NAVIC is the industry leader in non-destructive testing for weld inspection.

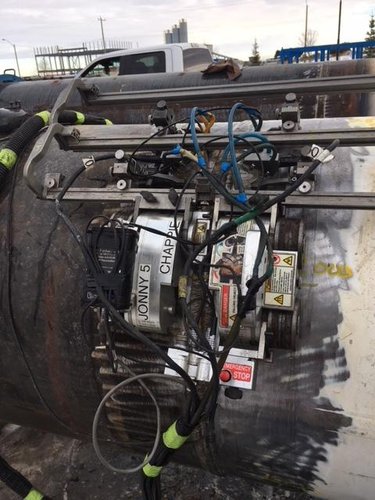

Customer Photos

Videos

Features

Motorized Driving and Steering

Variable drive speed and steering give the user precise control during weld inspection.

Rugged

Designed to handle intense tasks and challenging environments (dust-tight, watertight)

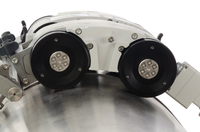

Magnetic Wheels

Magnetic wheels provide the foundation for scan operations on ferrous surfaces.

Low Profile Design

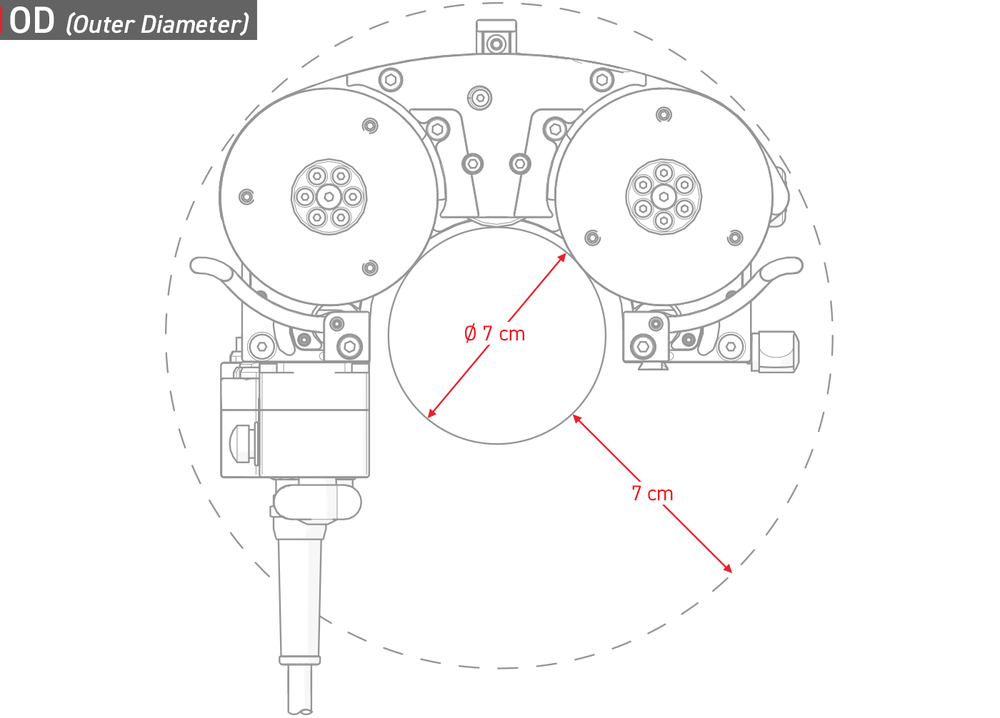

The NAVIC can circumnavigate pipes as small as 7 cm (2.75 in) OD while only requiring 7 cm (2.75 in) of radial clearance when low-profile scanning is needed.

Remote Control

The intuitive handheld remote control allows you to program drive paths from up to 30 m (100 ft) away. The ergonomic handheld controller includes drive paths and system diagnostics.

Battery Power

Order the NAVIC with the battery kit and avoid using heavy, cumbersome generators. These rechargeable batteries can power the NAVIC system and accessories for hours.

Many Accessories

Optional accessories enhance the NAVIC's capability: a battery-powered optical guide, onboard camera, backpack, cable management, preamp, and motorized couplant pump.

Warranty

Products are engineered and designed to perform flawlessly. Our products feature a limited warranty for three years.

Kit Contents

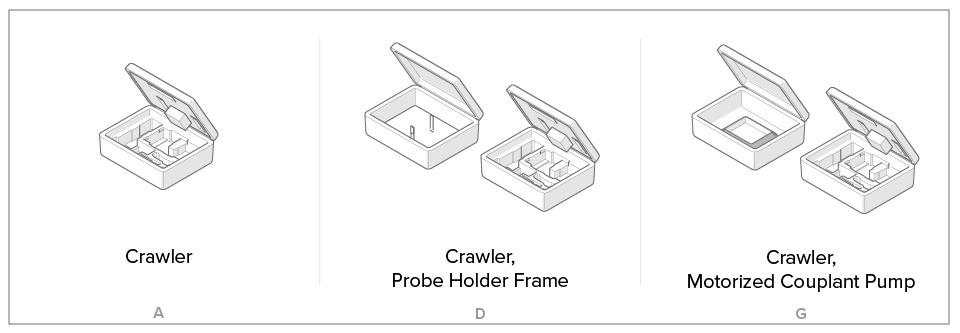

SCANNER

NAVIC base crawler

PARTS & ACCESSORIES

System controller

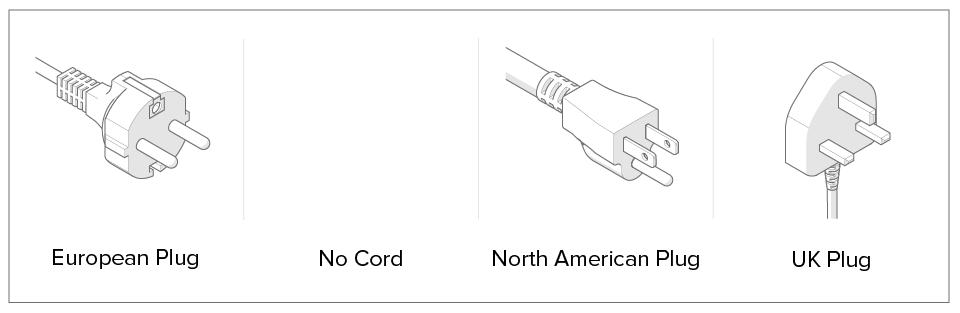

Power supply (North American, European or UK plugs available)

Umbilical, 5 m (15 ft), 10 m (30 ft), 15 m (50 ft) or 30 m (100 ft) lengths available

Handheld controller

Auxiliary cable, 6 m (20 ft)

Cable management, threaded mount (length dependent on umbilical length)

J300 encoder cable, 5 m (15 ft)

Installation/Removal mat

6 mm ID irrigation kit (7/16 in quick connect)

Lifting sling (safety tether)

User manual

Cap: NAVIC hinge cover

Plug

Rugged carrying cases (various types based on chosen accessories) x2 – x3

TOOLS

3 mm hex driver

3 mm flat driver

Wrench for pivot button adjustment

Component Identification

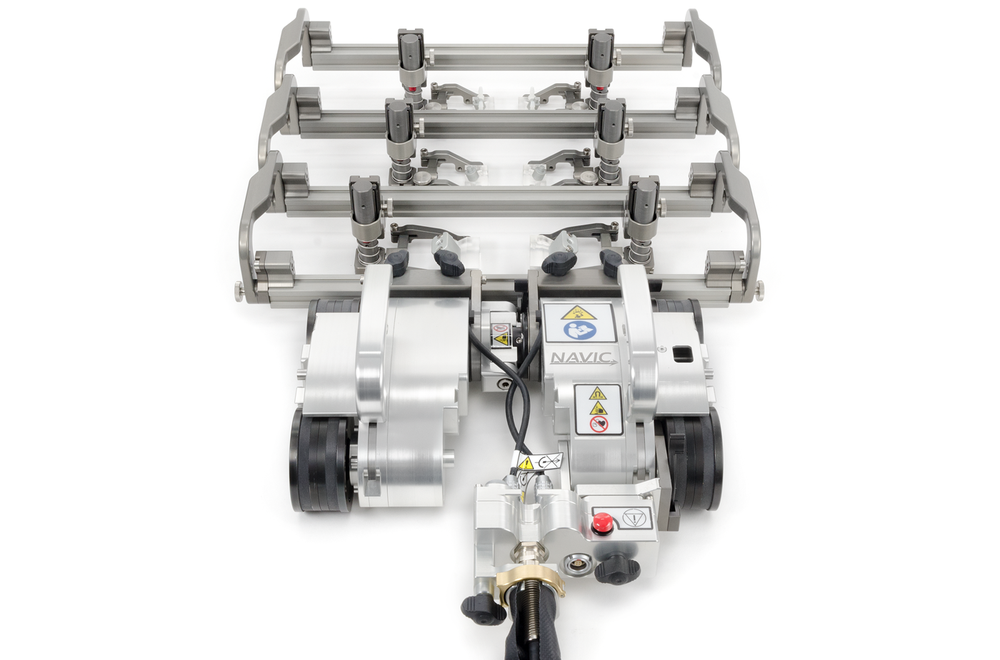

Base Crawler

The robust base crawler carries probe holder frames, raster arms and many weld and corrosion inspection accessories.

Integrated Encoder

A spring-loaded encoder maintains surface contact on all various scan surface diameters.

Magnetic Wheels

Robust magnetic wheels ensure the crawler remains fixed to any ferrous surface.

System Controller

The system controller connects the user instrument and handheld controller to the base crawler and is compatible with North American and European power sources.

Umbilical

The umbilical connects the crawler and the system controller, providing communication and power between the components.

Handheld Controller

The handheld controller joysticks contain the NAVIC operating system and control the speed and steering of the base crawler. At the same time, the intuitive touchscreen allows for more intricate raster path and drive programming.

Parts & Add-Ons

Battery Powered Optical Guide

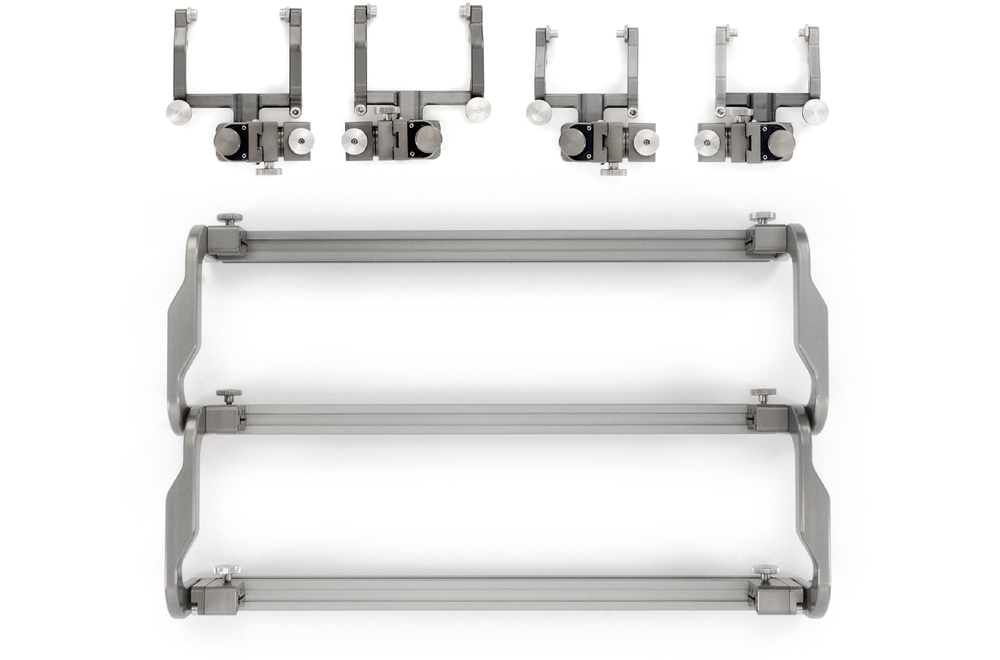

Low Profile Probe Holder Frame

Motorized Couplant Pump

Motorized Pump/Umbilical Case - Extra Large

Optical Guide

Pivoting Probe Holder Frame

Preamp Bracket

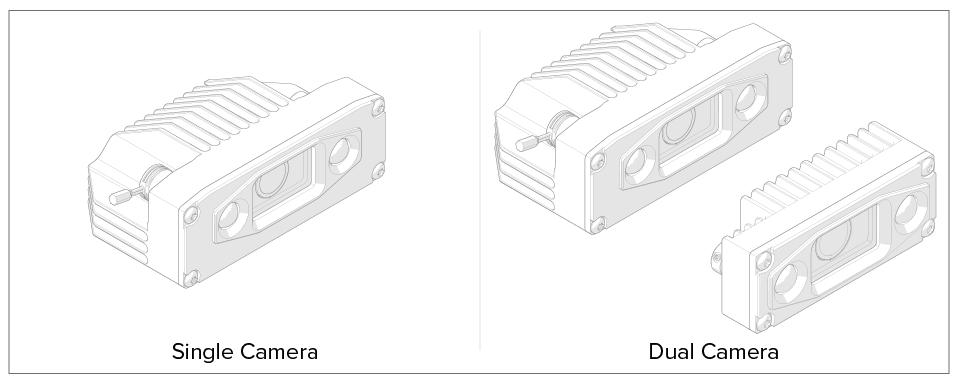

RECON - Fixed Camera Kit

Tracker

Vertical Probe Holder Frame

Vertical Probe Holder Frame - 2 Probe

Vertical Probe Holder Frame - 2 Probe Add-On

Related Products

Specifications

GENERAL

Idler Encoder (Right Module): 13.78 counts/mm (349.9 counts/inch)

Motor Encoder (Left Module): 872.5 counts/mm (22162.8 counts/inch)

Crawler’s Vertical Payload: 10 kg (22 lb)1

Driving Speed: Variable 0 – 25 cm/sec (0 – 10 in/sec)

Power Requirements: 100-240VAC, 50/60Hz, 3.5 Amps

Umbilical Lengths: 5 m (15 ft), 10 m (30 ft), 15 m (50 ft) to 30 m (100 ft)2

Inspection Surface: Ferrous

Maximum Backpack payload: 1.36 kg (3 lb)3

PIPE RANGE

Pipe Range, Circumferential: 7 cm (2.75 in) to flat pipe

Range, Internal Circumferential: 61 cm (24 in) to flat

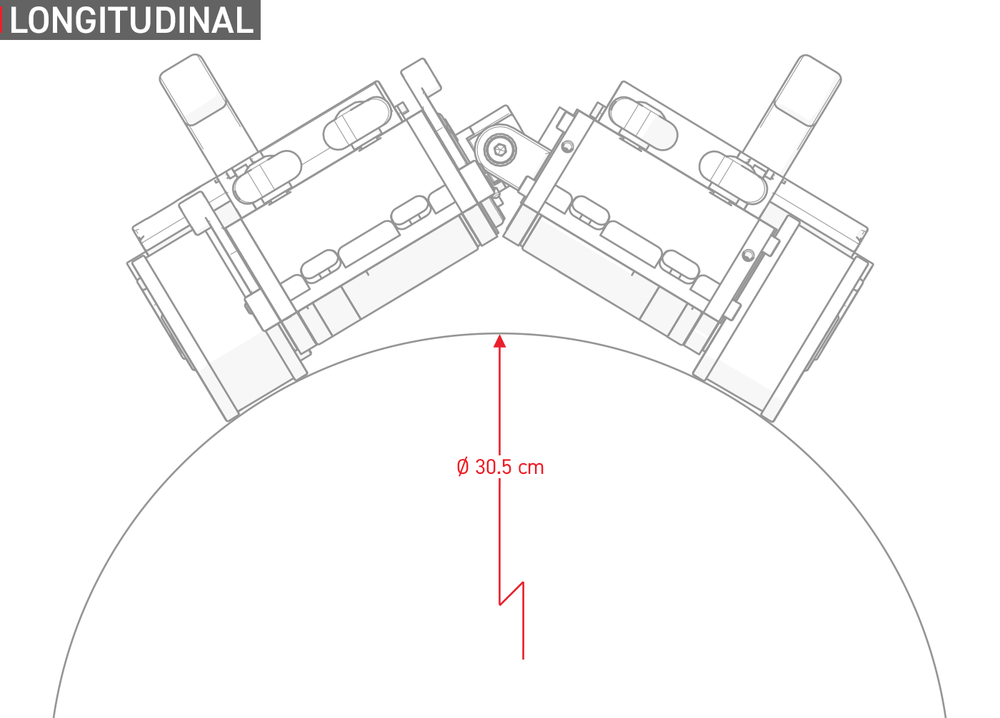

Pipe Range, Longitudinal: 30.5 cm (12 in) to flat

RADIAL CLEARANCE

Radial Clearance, Pipes under 20 cm (8 in): 7 cm (2.75 in)4

Radial Clearance, Pipes over 20 cm (8 in): 8.15 cm (3.2 in)4

REGULATIONS

CE: European Union CE Declaration – Compliance with essential requirements and provisions of European Union directives.5

FCC: Compliance with Part 15 of FCC rules.5

Industry Canada: CAN ICES-3 (A)/NMB-3(A) – This class A digital apparatus complies with Canadian ICES-003.5

UKCA: United Kingdom Conformity Assessed – Compliance with relevant UK statutory requirements and legislation.5

SIZE & WEIGHT

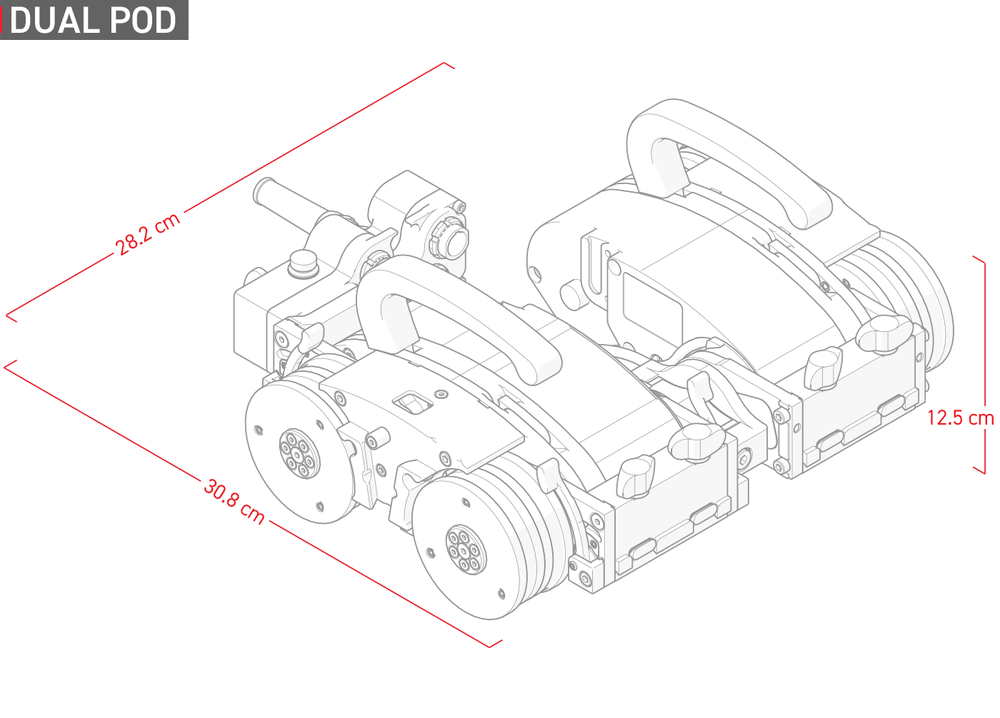

Base Crawler Height (including handles): 12.5 cm (4.9 in)

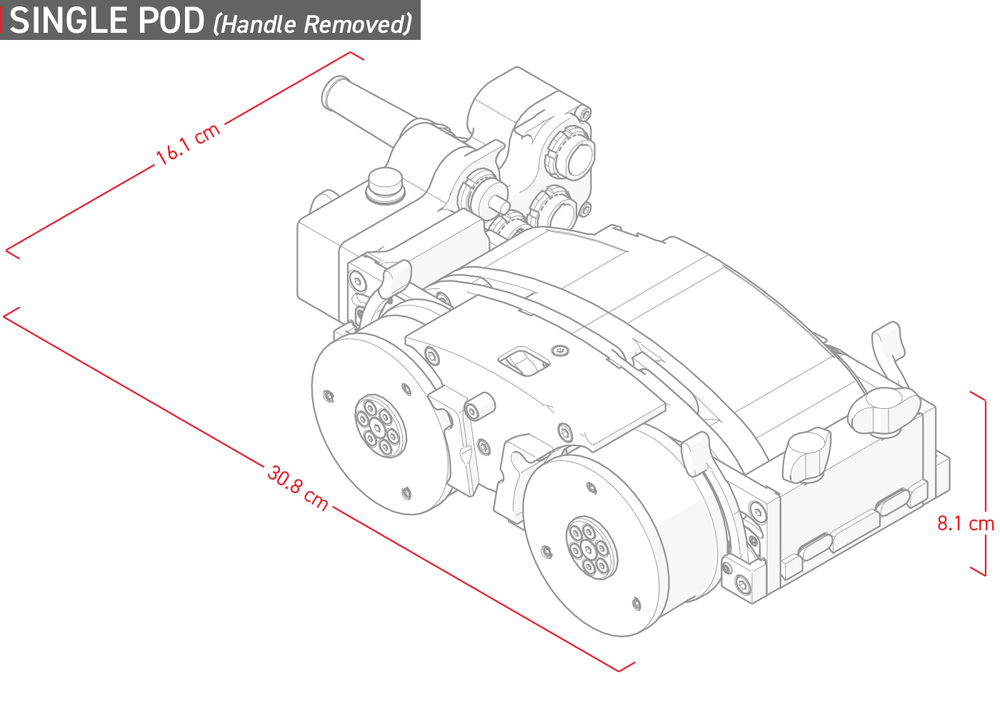

Base Crawler Height (handles removed): 8.1 cm (3.2 in)

Base Crawler Width (Dual Pod): 28.2 cm (11.1 in)

Base Crawler Length: 30.8 cm (12.1 in)6

Base Crawler Width (Single Pod): 16.1 cm (6.3 in)

Base Crawler Weight: 7.7 kg (17 lb)7

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 50°C (122°F)

Environmental Sealing: Dust-tight, water-tight (not submersible)

Maximum Inspection Surface Temperature: 150°C (302°F)8

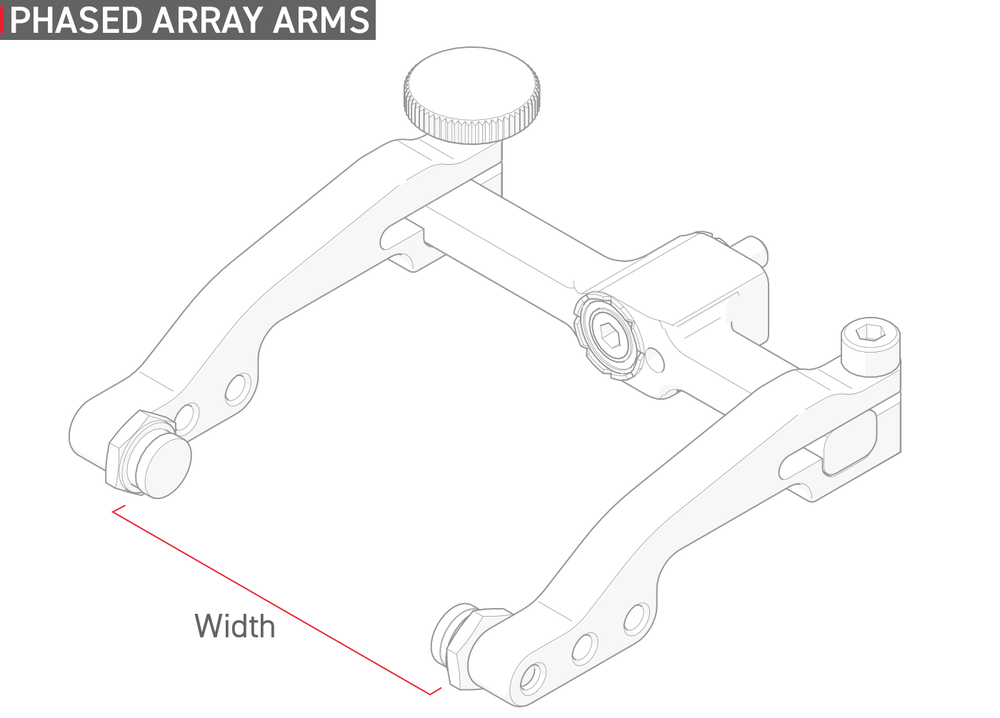

PHASED ARRAY PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 17.1 mm (0.7 in)

Maximum Wedge Width: 57.6 mm (2.3 in)9

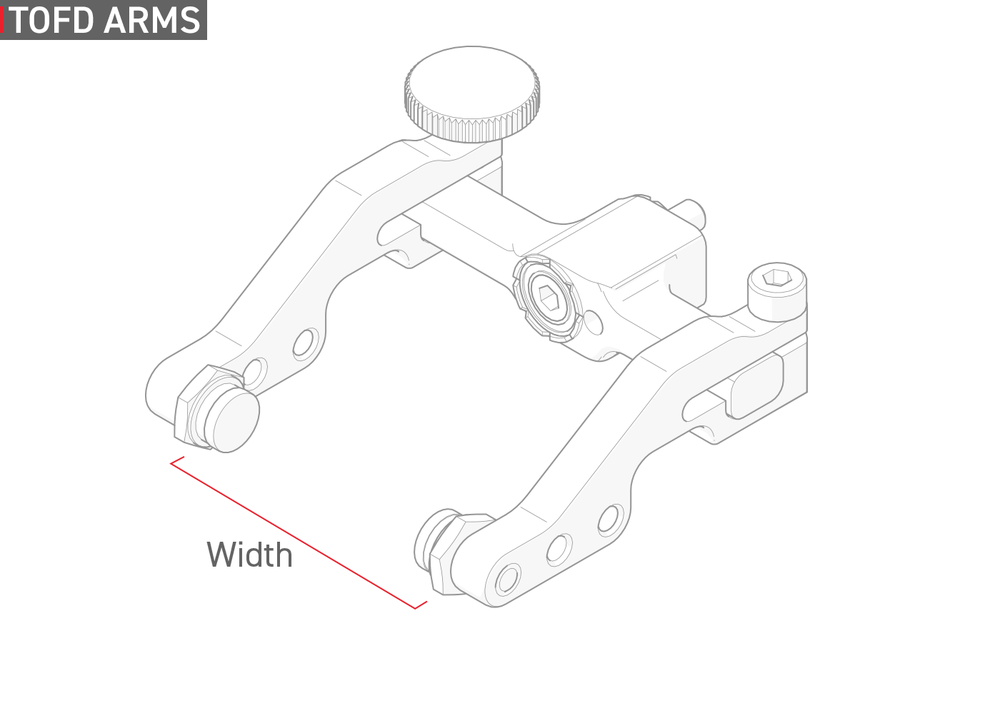

TOFD PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 17.1 mm (0.7 in)

Maximum Wedge Width: 45 mm (1.8 in)9

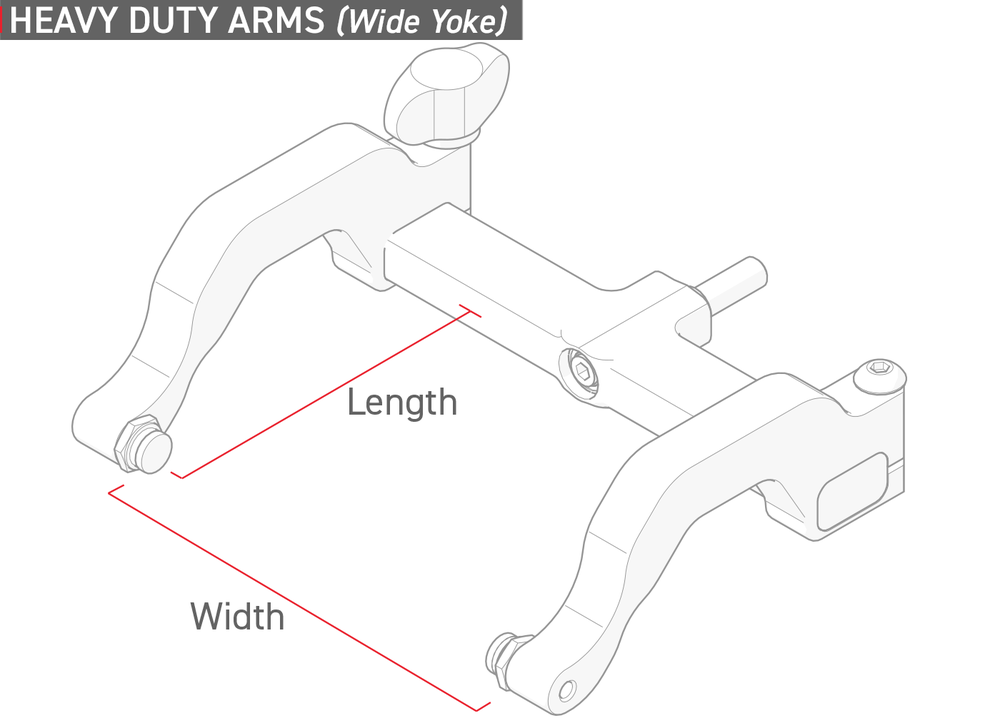

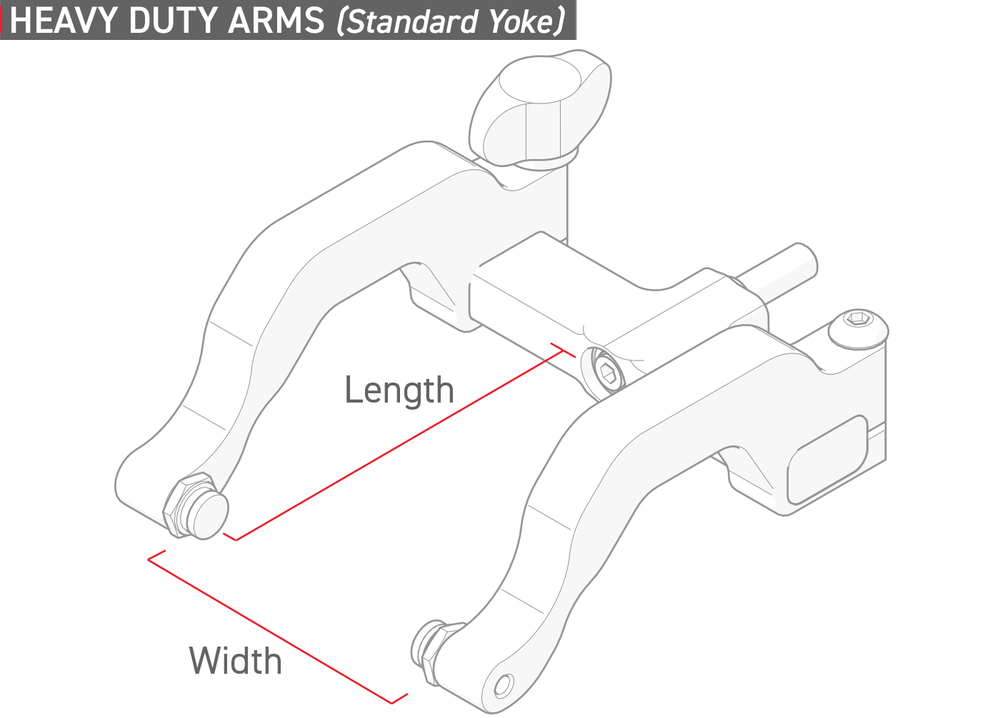

HEAVY DUTY VERTICAL PROBE HOLDER SPECIFICATIONS

Standard Yoke

Minimum Wedge Width: 17.4 mm (0.69 in)

Maximum Wedge Width: 55 mm (2.17 in)

Standard Length: 63.5 mm (2.5 in)

Wide Yoke

Minimum Wedge Width: 17.4 mm (0.69 in)

Maximum Wedge Width: 93.8 mm (3.69 in)

Wide Length: 63.5 mm (2.5 in)

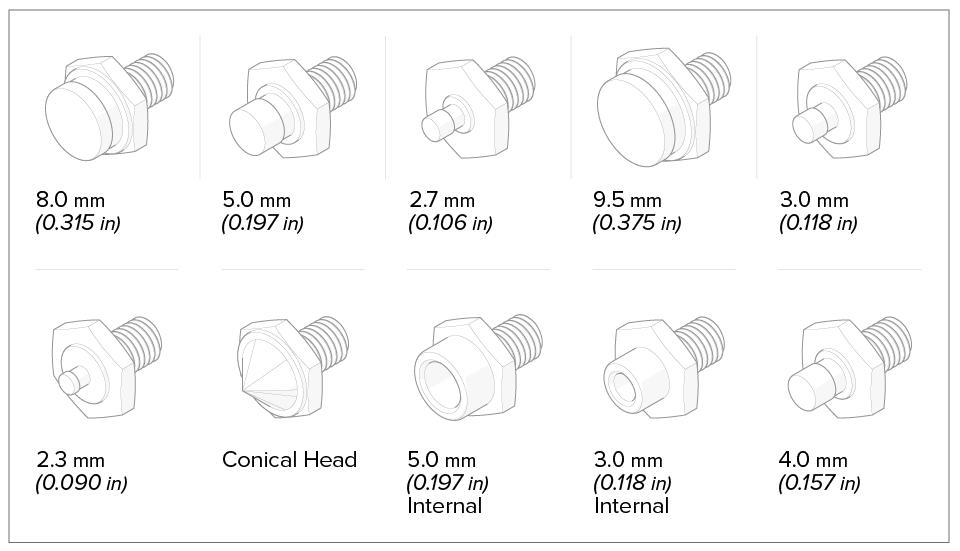

Probe Holder Pivot Buttons

01

Pivot Hole Size: 8.0 mm (0.315 in)

Wedge Type: Olympus PA

Hex Size: 9.53 mm (3/8 in)

02

Pivot Hole Size: 5.0 mm (0.197 in)

Wedge Type: Olympus TOFD, Olympus A27 DMA

Hex Size: 9.53 mm (3/8 in)

03

Pivot Hole Size: 2.7 mm (0.106 in)

Wedge Type: Sonatest DAAH PH

Hex Size: 9.53 mm (3/8 in)

04

Pivot Hole Size: 9.5 mm (0.375 in)

Hex Size: 11.1 mm (7/16 in)

06

Pivot Hole Size: 3.0 mm (0.118 in)

Hex Size: 9.53 mm (3/8 in)

07

Pivot Hole Size: 2.3 mm (0.09 in)

Hex Size: 9.53 mm (3/8 in)

08

Pivot Hole Size: Conical Head

Hex Size: 9.53 mm (3/8 in)

09

Pivot Hole Size: 5 mm (0.197 in)

Wedge Type: Internal Zetec PA/TOFD, Phoenix TOFD

Hex Size: 9.53 mm (3/8 in)

11

Pivot Hole Size: 5.6 mm (0.221 in)

Hex Size: 9.53 mm (3/8 in)

- Performance may vary with the surface type. Heavy payloads may require reduced speeds.

- Custom umbilical lengths are available.

- The backpack is not compatible with older-generation NAVIC crawlers.

- Handles removed.

- For a complete description of regulatory certifications, please contact JIREH.

- The length of the unit includes umbilical strain relief.

- Crawler weight excludes umbilical.

- The automated crawler medium temperature add-on kit is required when the inspection surface temperature measures between 50°C (122°F) and 150°C (302°F).

Duty cycling may be required if the ambient temperature is >25°C. - Some arm styles may provide additional maximum wedge width. Contact Jireh Industries for details.

Technical specifications are subject to change.

Documents

To download the user manuals and additional documentation for the scanner, click the appropriate link below.

(specifications are subject to change)