Inspection on surfaces up to 350°C

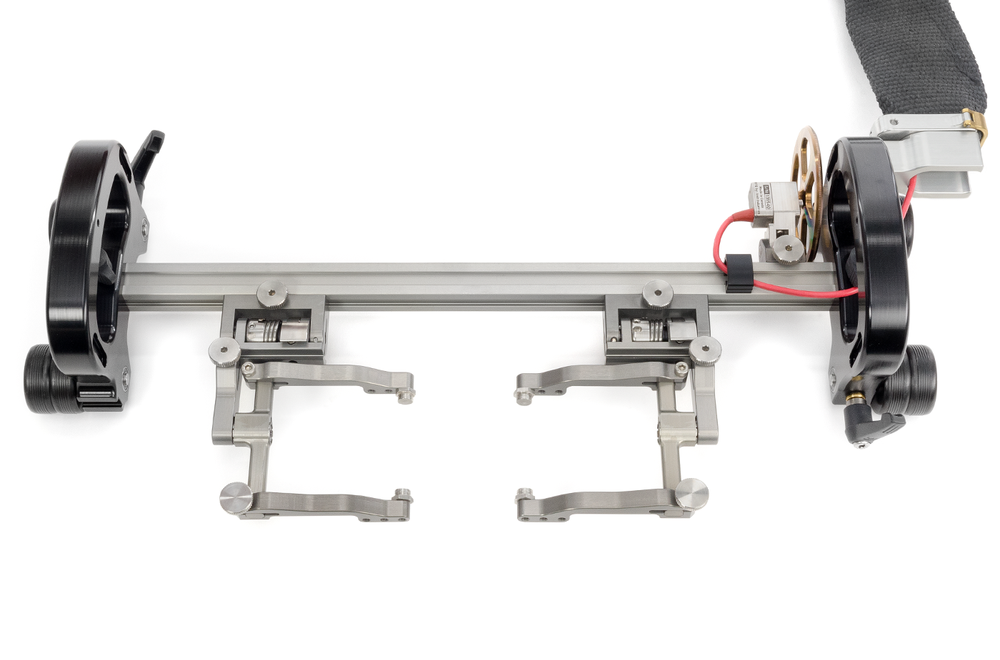

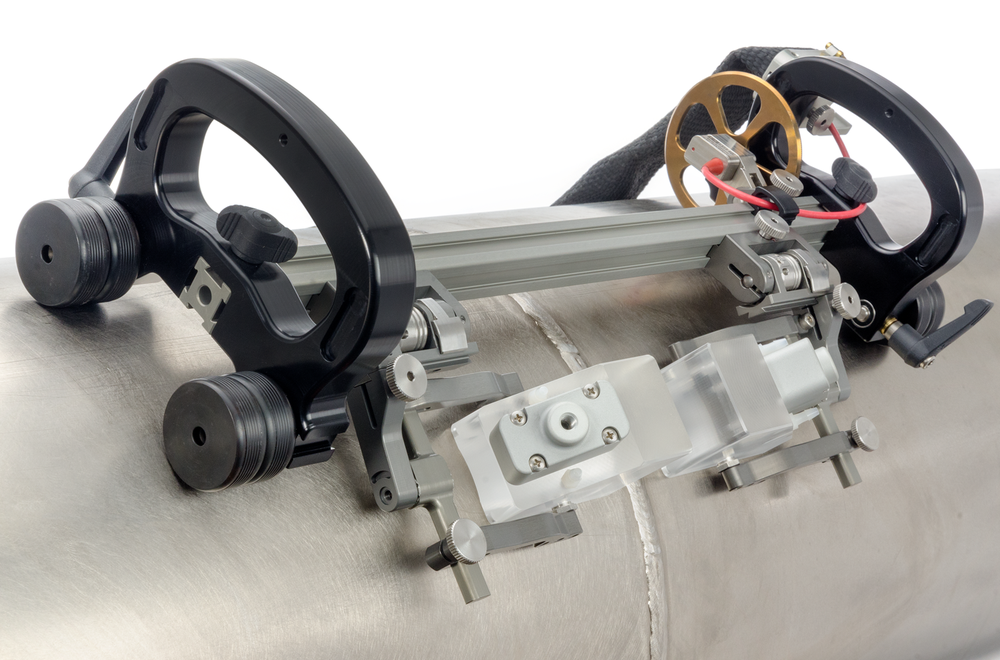

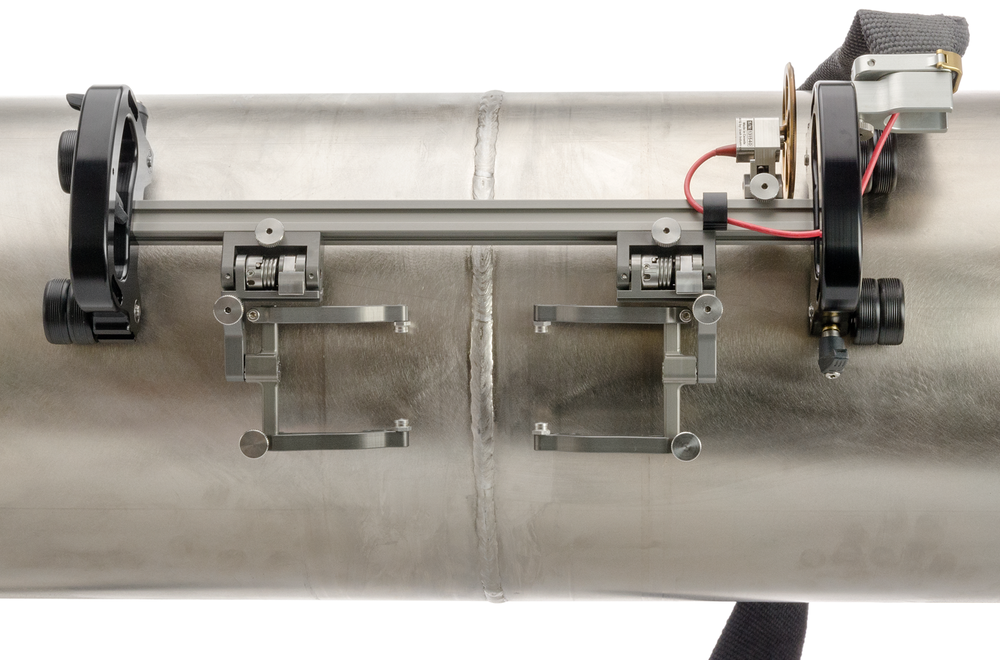

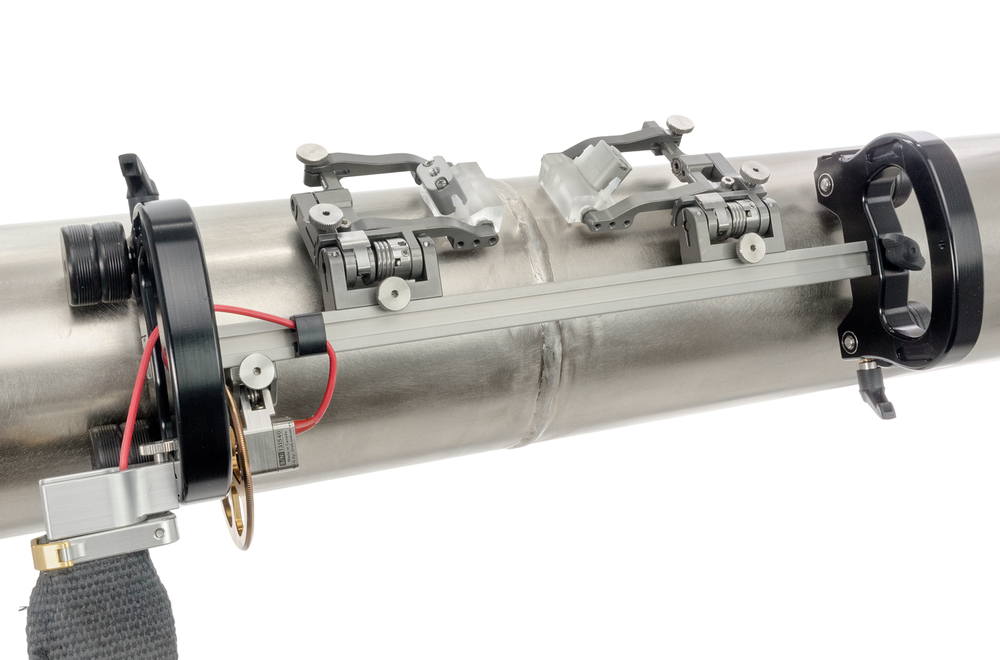

Perform UT scans while pipes and tubes remain online with surface temperatures up to 350°C (662°F). The STIX - High Temperature Weld Frame Scanner provides encoded feedback for 2 probes.

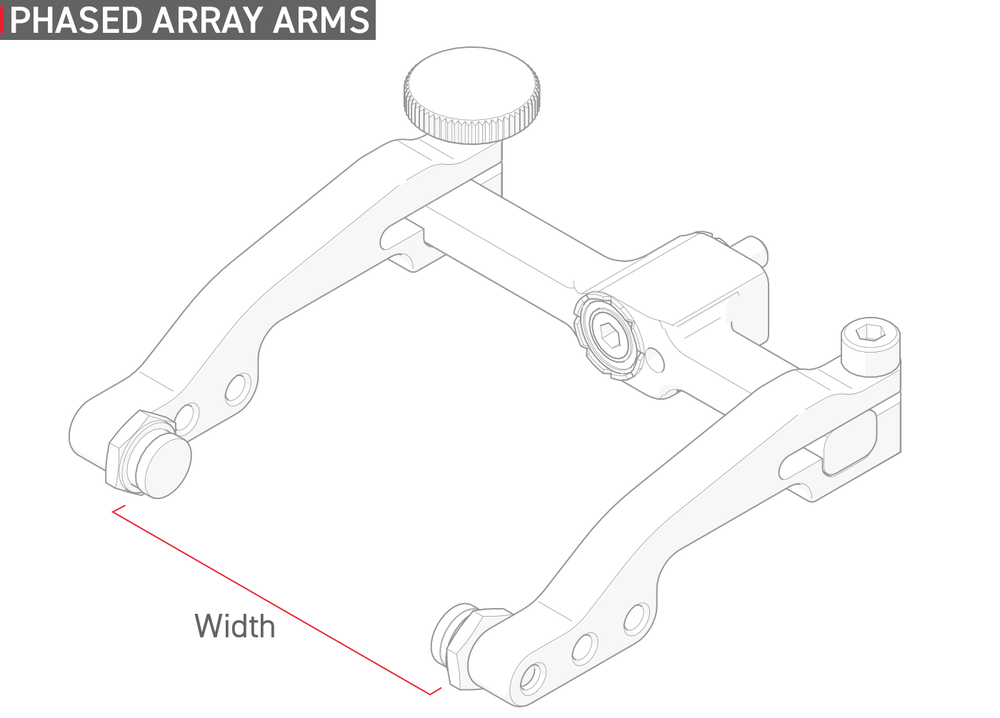

Alternate probe holder arms are available. Contact JIREH for more information.

Videos

Features

High Temperature Encoder

Track the scanner movement with confidence. The heat of the scan surface dissipates across the oversized encoder wheel; this protects the components of the precision encoder, which is compatible with all industry-standard instruments.

Handle

Handles are available to assist with scanner control.

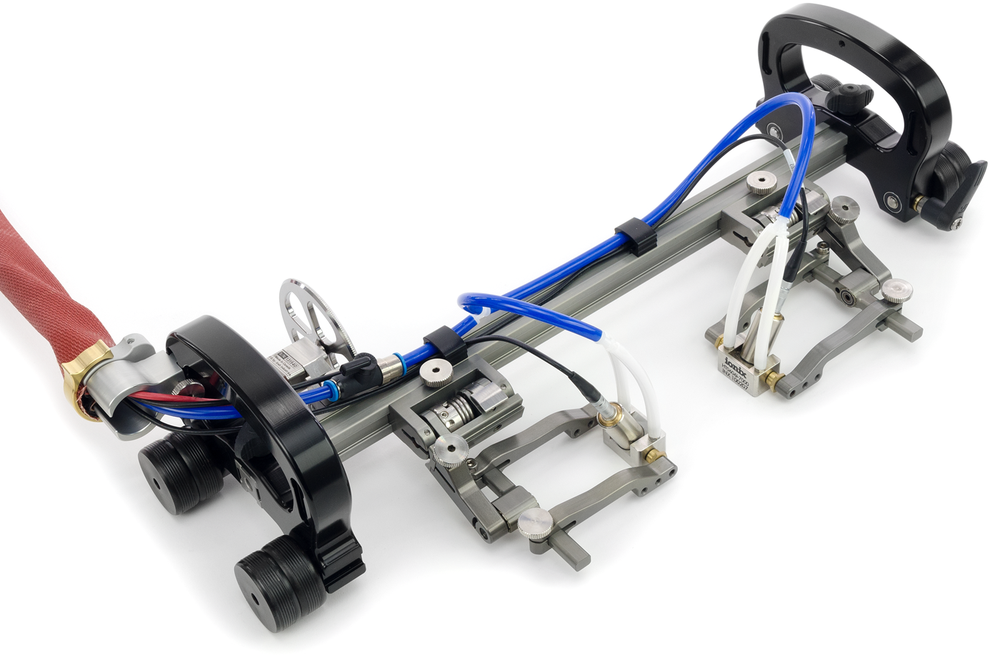

High Temperature Cable Management

High temperature cable management protects cables, tubes and hoses from contact with hot surfaces.

High Temperature Magnetic Wheels

The magnetic wheels are coated with urethane to reduce the effects of foreign debris obstructing the rolling of the scanner. To further increase the system's flexibility, the wheels are also stackable to increase the magnetic attraction when required.

Brake

Lock the scanner in place when required.

Cable Clips

Route and organize encoder cables.

Warranty

3-year limited warranty on all products.

Component Identification

Magnetic Wheels

High temperature magnetic wheels affix the scanner to the ferrous inspection surface.

Handle

Handles offer convenient scanner control.

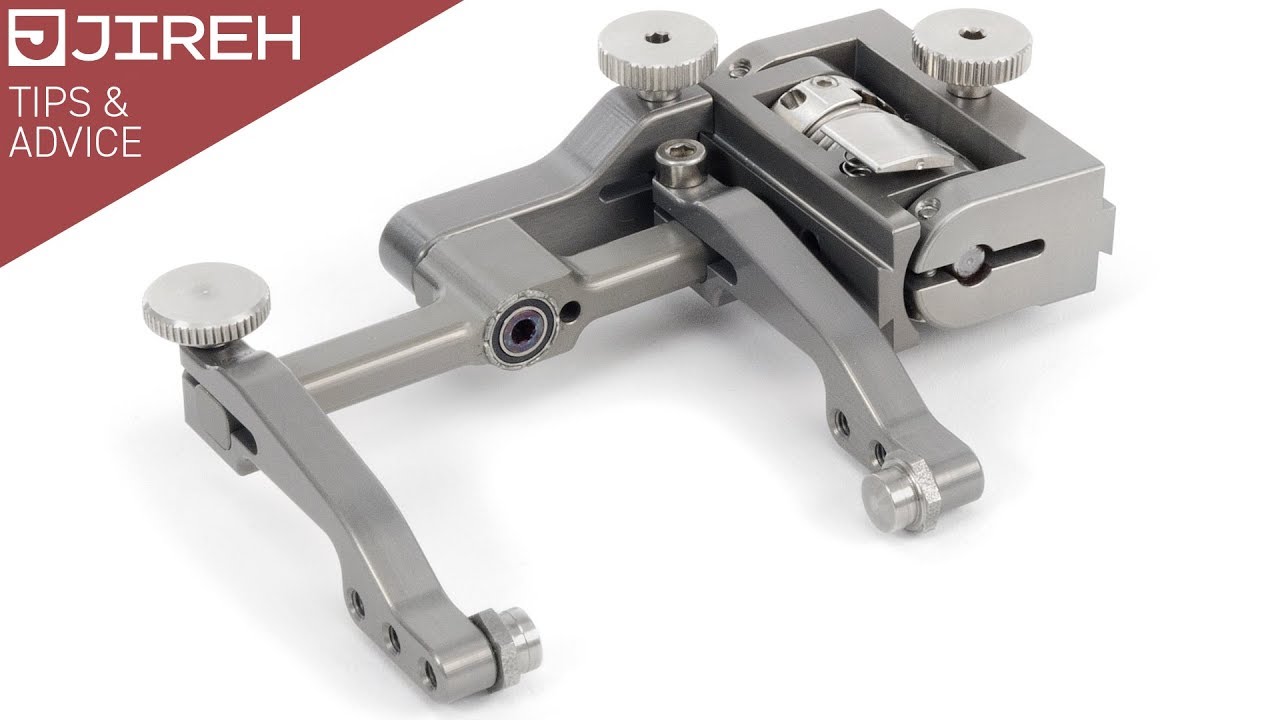

Slip Joint Probe Holder

The slip joint probe holder may be configured to hold many industry-standard probe and wedge combinations.

Brakes

Prevent unwanted scanner motion and hold the position.

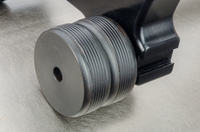

High Temperature Encoder Wheel

Collect precise encoder feedback with this unique encoder. Explicitly designed to dissipate heat from the scan surface, the encoder is rated for operation up to 350°C (662°F).

Cable Clip

Route encoder cables and irrigation through convenient, easy-to-use cable clips.

High Temperature Cable Management

Protect encoder cables, instrument cabling and irrigation hoses with heavy duty cable management.

Parts & Add-Ons

Related Products

Specifications

GENERAL

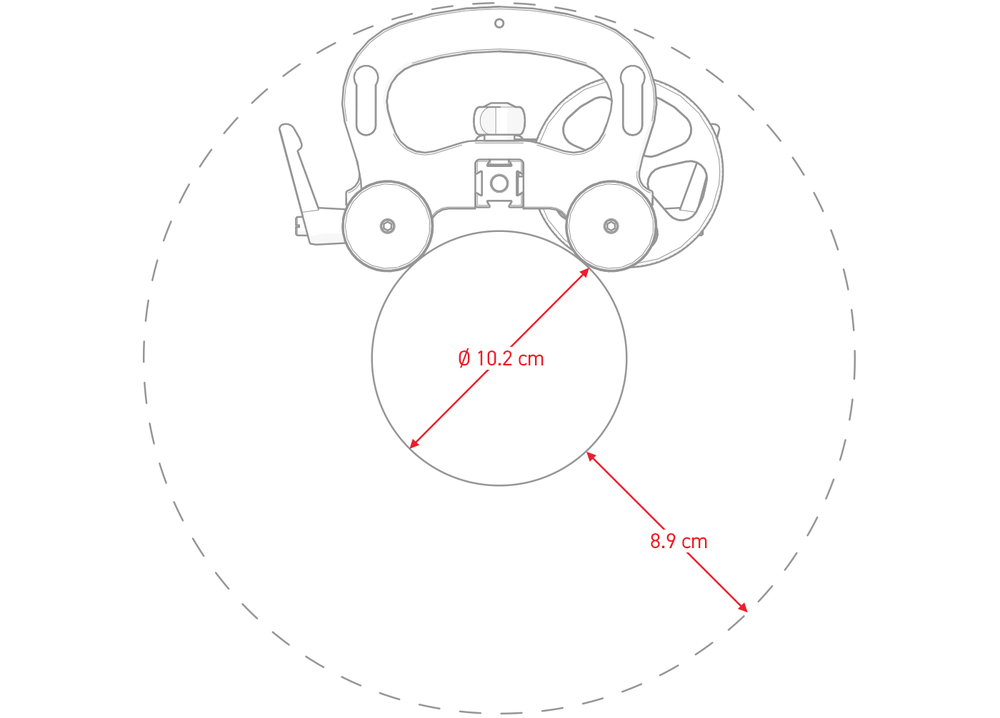

Pipe Range, Circumferential: 10.2 cm (4 in) to flat

Pipe Range, Internal: Flat to 152.4 cm (60 in)

Encoder Resolution: 4.28 counts/mm (108.7 counts/inch)

Probe Holding Capacity: 2 or 4 wedges

Encoder Cable Length: 5 m (16.4 ft)1

Inspection Surface: Ferrous materials

RADIAL SCANNER CLEARANCE

Radial Clearance: 8.9 cm (3.5 in)

SIZE & WEIGHT

Frame Height: 10.5 cm (4.1 in)

Frame Width: 17.5 cm (6.9 in)

Frame Length: 45.4 cm (17.9 in)

Frame Weight: 1.3 kg (2.8 lb)

Shipping weight: TBA kg (TBA)2

ENVIRONMENTAL SPECIFICATIONS

Operating Environment: -20°C (-4°F) to 350°C (662°F)

Environmental Sealing: Watertight (submersible), Contact JIREH for details

PHASED ARRAY PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 17 mm (0.67 in)

Maximum Wedge Width: 55.8 mm (2.2 in)3

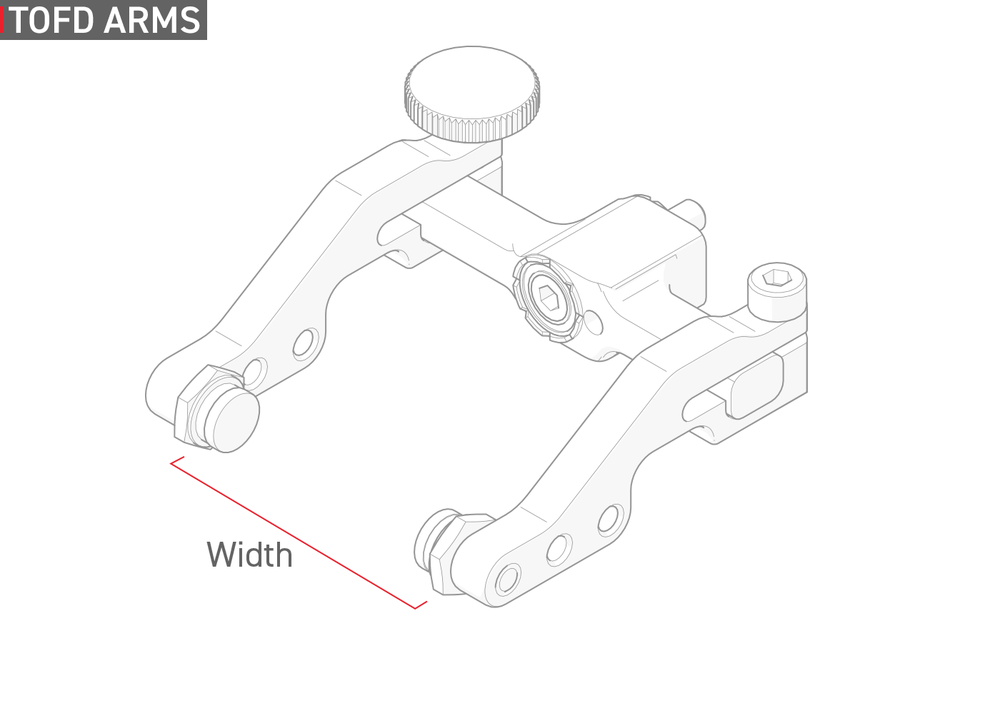

TOFD PROBE HOLDER SPECIFICATIONS

Minimum Wedge Width: 17 mm (0.67 in)

Maximum Wedge Width: 44.4 mm (1.75 in)3

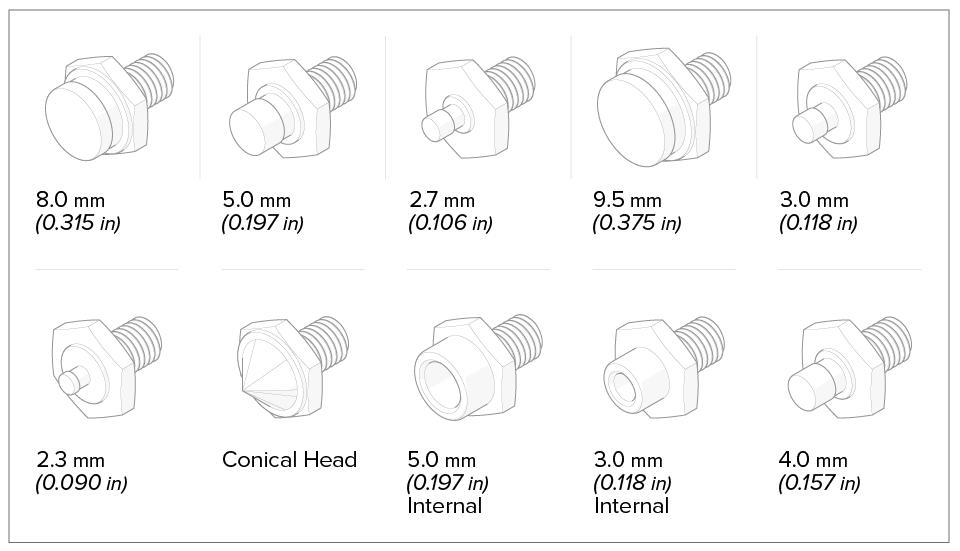

Probe Holder Pivot Buttons

01

Pivot Hole Size: 8.0 mm (0.315 in)

Wedge Type: Olympus PA

Hex Size: 9.53 mm (3/8 in)

02

Pivot Hole Size: 5.0 mm (0.197 in)

Wedge Type: Olympus TOFD, Olympus A27 DMA

Hex Size: 9.53 mm (3/8 in)

03

Pivot Hole Size: 2.7 mm (0.106 in)

Wedge Type: Sonatest DAAH PH

Hex Size: 9.53 mm (3/8 in)

04

Pivot Hole Size: 9.5 mm (0.375 in)

Hex Size: 11.1 mm (7/16 in)

06

Pivot Hole Size: 3.0 mm (0.118 in)

Hex Size: 9.53 mm (3/8 in)

07

Pivot Hole Size: 2.3 mm (0.09 in)

Hex Size: 9.53 mm (3/8 in)

08

Pivot Hole Size: Conical Head

Hex Size: 9.53 mm (3/8 in)

09

Pivot Hole Size: 5 mm (0.197 in)

Wedge Type: Internal Zetec PA/TOFD, Phoenix TOFD

Hex Size: 9.53 mm (3/8 in)

11

Pivot Hole Size: 5.6 mm (0.221 in)

Hex Size: 9.53 mm (3/8 in)

- Custom umbilical lengths are available.

- Approximate shipping weight of standard kit contents.

- Some arms styles may provide additional maximum wedge width. Contact Jireh Industries for details.

Technical specifications subject to change.